Menu

THE BLACKSMITH

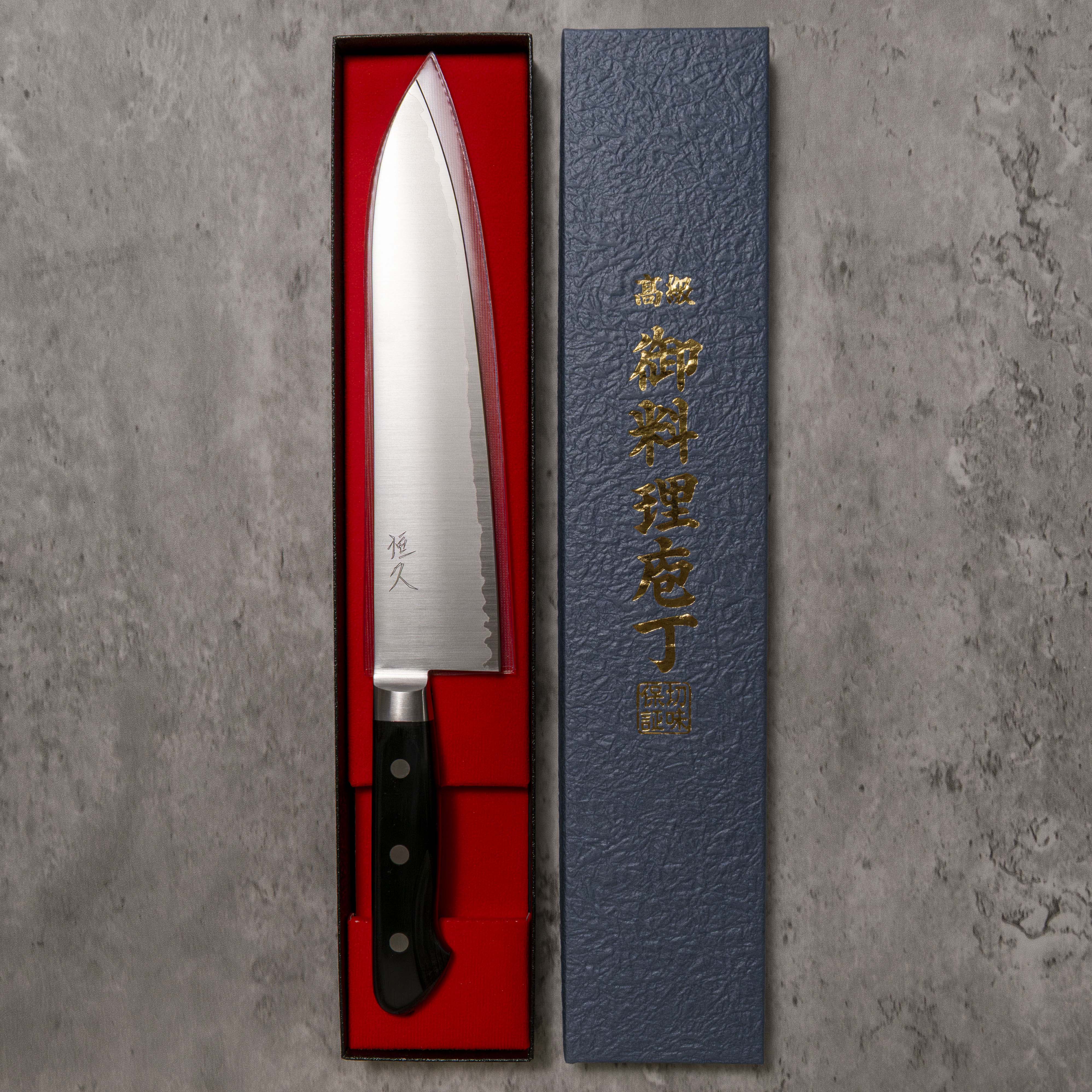

TSUNEHISA

- Choosing a selection results in a full page refresh.

Usually ready in 1 hour

| Blade Length | 210 mm |

| Total Length | 335 mm |

| Steel | VG-1 Gold |

| Handle | Pakka wood |

| Ferrule | Welded Steel |

| Rockwell | 61-63 |

| Height Spine to heel | 45 mm |

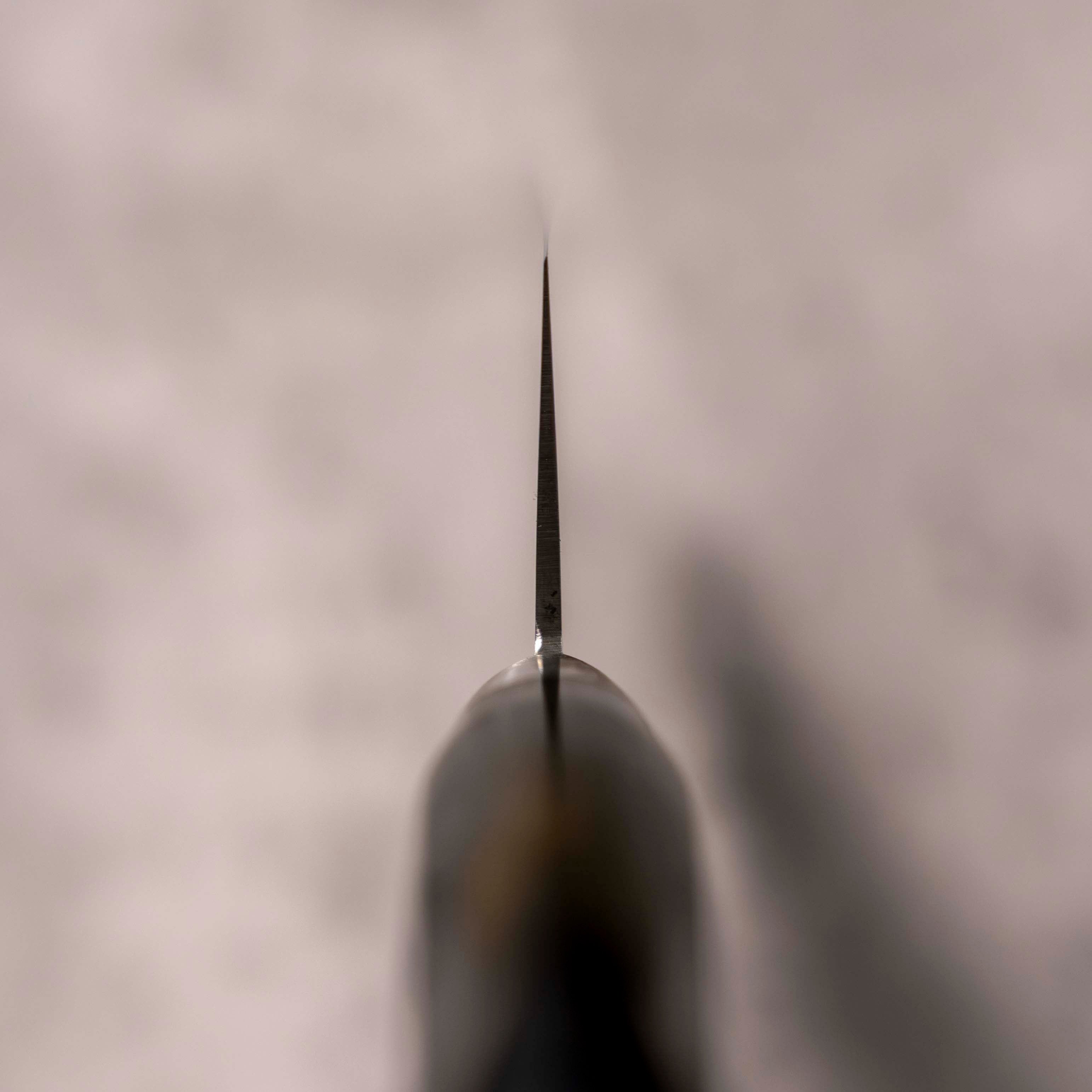

| Width at Spine | 1.77 mm |

| Weight | 163 grams |

| Bevel | Double (50/50) |

Follow these care recommendations for your Japanese knives to protect the edge and keep them sharp as long as possible:

All products are shipped within 24 hours. We offer same day shipping for products ordered by 12pm. Please allow 4-7 business days for your shipment to arrive with standard shipping. Expedited shipping options are also available at checkout.

We offer free shipping on orders within Canada over $150 CAD and free shipping on orders to the US over $200 USD.

Curbside pick-up is available at both our Hamilton and Etobicoke locations.

To make sure our customers are always satisfied, we offer full refunds on products for 14 days after receiving them. See our full return policy for details.

More questions? Check out our shipping policy, our return policy, or reach out to us directly.

The Gyuto is the Japanese equivalent to the western style chef’s knife and is without question the most versatile knife shape. It ranges in size from 180 mm (7 inches) to 240 mm (10 inches), making it longer than the Santoku and Bunka. This length makes it adept at handling almost any task you'll come across in the kitchen, from mincing small ingredients to chopping through larger fruits and vegetables. The longer the knife, the more time it will take to grow accustomed to its length, but the more versatile it will be.

VG1 is the starting point of the V steel series, which is refined using high-quality raw materials with minimal impurities. It is a stainless blade steel with a fine structure that achieves the four key requirements for excellent knives: high hardness, high toughness, high wear resistance, and high corrosion resistance through its mix of Carbon (C), Chromium (Cr), and Molybdenum (Mo).

Chemical Composition:

C 0.95-1.05% | Cr 13.0-15.0% | Mo 0.2-0.4%

LOW MAINTENANCE

Stainless steel Japanese knives are made in a process called “Sanmai” or “Forge welding” where two softer layers of stainless steel are laminated around a harder core layer of stainless steel. All three of these layers are rust resistant and therefore are not susceptible to rust or discoloration. The softer outer layers of steel are used to make the knife more durable and flexible while the harder core layer is used to provide better edge retention to the blade.

Tsunehisa seeks to make great knives at affordable prices. Their knives are machine forged, as opposed to being hand forged; however, many of the knife making processes are still done by hand. This combination of machine and human touch ensures the knives have a fantastic fit and finish, high performance capabilities, and extreme consistency. These knives are fantastic for the home cook or the professional looking for great performance, easy maintenance, and beautiful aesthetics.