Menu

THE BLACKSMITH

YU KUROSAKI

- Choosing a selection results in a full page refresh.

| Blade Length | 165 mm |

| Total Length | 310 mm |

| Steel | VG XEOS |

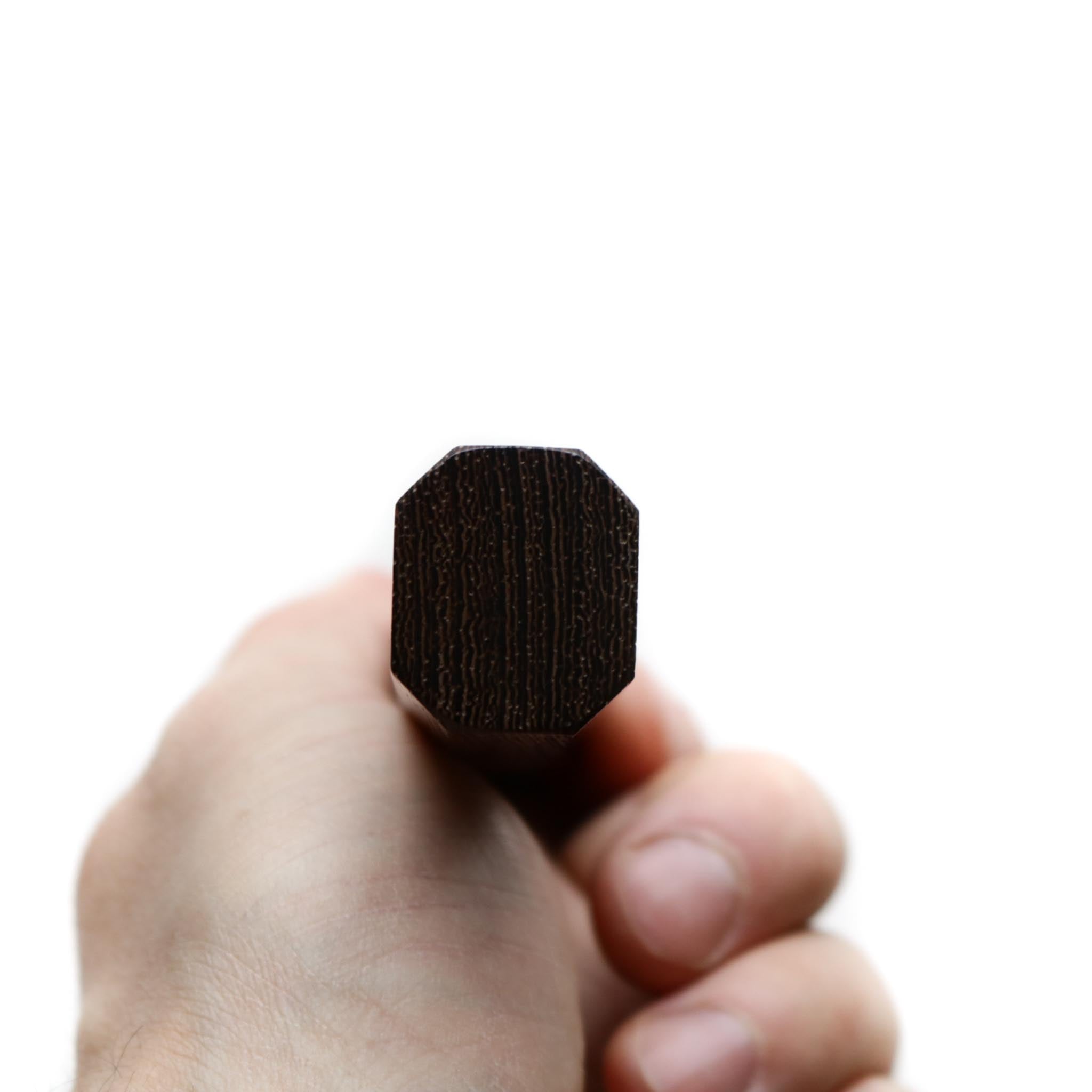

| Handle | Wenge |

| Ferrule | Buffalo Horn |

| Rockwell | 62 |

| Height Spine to heel | 51.4 mm |

| Width at Spine | 2.1 mm |

| Weight | 161 grams |

| Bevel | Double (50/50) |

Yu Kurosaki

These are easily some of the most beautiful knives we have at the shop. Made by Master Blacksmith Yu Kurosaki who works out of a newly constructed shop just steps from the Takefu knife village community centre. He began his blacksmith journey in 2002 at Kanehiro and now only 17 short years later he has been awarded his Master Blacksmith designation by the Echizen Blacksmith Foundation. His knives represent the future of Blacksmithing in Japan as he focuses on traditional technique while using innovative and progressive design's and finishes that have garnered the attention of many chef's around the globe. Simply put his knives are stunning to look at and dare we say perform even better than they look.

Takefu Knife Village

The Takefu Knife Village is a cooperative workshop in the Echizen region of Japan. It is the home to a long list of blacksmiths that we work with and many young and upcoming apprentices learning the trade. The area has a 700 year long history of smithing with roots in agricultural tools turned cutlery powerhouse.

The Knife

Fantastic Nakiri for home users especially vegetarians/vegans. Nakiri are designed specifically for vegetable chopping due to their tall blades and flat edges which are ideal for up and down chopping. This knife has a very slight curve to the blade though so if you prefer to use a rocking motion when chopping you're perfectly capable of doing so. Nice and light, thin blade that has an amazing cutting feel; it's balance is slightly blade heavy. We like to call Nakiri the stir-fry knife as it can help you get one done in mere minutes once you've mastered the up and down chopping motion.

We don't know much about VG XEOS steel other than that it is produced by the Takefu Special Steel Company. It is a brand new steel type specifically designed to meet the demands of modern kitchens and as far as we know, Kurosaki-san is the first to begin working with it. You can expect the same high level of fit and finish, grinds and edge geometry on this new Gekko series as with all of Kurosaki-san's knives. The following description is taken directly from the Takefu Special Steel company website and is the only information available on the steel type at the moment.Follow these care recommendations for your Japanese knives to protect the edge and keep them sharp as long as possible:

All products are shipped within 24 hours. We offer same day shipping for products ordered by 12pm. Please allow 4-7 business days for your shipment to arrive with standard shipping. Expedited shipping options are also available at checkout.

We offer free shipping on orders within Canada over $150 CAD and free shipping on orders to the US over $200 USD.

Curbside pick-up is available at both our Hamilton and Etobicoke locations.

To make sure our customers are always satisfied, we offer full refunds on products for 14 days after receiving them. See our full return policy for details.

More questions? Check out our shipping policy, our return policy, or reach out to us directly.

The Nakiri is designed for vegetable chopping. It has a flat profile (less curved blade) that helps the knife make consistent contact with the cutting board when using an up and down chopping motion, helping to avoid pesky accordions of stuck together ingredients. Any well rounded kit should contain a Nakiri, but if this is your first knife you might consider a Gyuto, Santoku or Bunka, as their pointed tips makes them more versatile.

VGXEOS is a new steel type developed by the Takefu Steel Company, which uses a special melting method that improves wear resistance, strength, and quenching properties. It offers hardness and strength while maintaining a high resistance to corrosion. It has been praised as: “A new steel grade that heralds the dawn of a new stage in cutlery (EOS).”

Chemical Composition:

Not disclosed by Takefu Steel Company

LOW MAINTENANCE

Stainless steel Japanese knives are made in a process called “Sanmai” or “Forge welding” where two softer layers of stainless steel are laminated around a harder core layer of stainless steel. All three of these layers are rust resistant and therefore are not susceptible to rust or discoloration. The softer outer layers of steel are used to make the knife more durable and flexible while the harder core layer is used to provide better edge retention to the blade.

Master Blacksmith Yu Kurosaki works out of a newly constructed shop just steps from the Takefu knife Village community centre in Echizen City, Fukui Prefecture, Japan. He began his blacksmith journey in 2002 at Kanehiro Hamono, apprenticing under master blacksmith Hiroshi Kato-san (Traditional Master Craftsman, or “Dentou-kougeishi”, with over 50 years experience). 17 years later, he became the youngest blacksmith to be awarded the same Traditional Master Craftsman honour bestowed upon his mentor. His knives represent the future of blacksmithing in Japan, as he focuses on traditional techniques while using innovative and progressive designs and finishes that have garnered the attention of many chefs around the globe. Simply put, his knives are stunning to look at and perform even better than they look.